Blog Archives

HP’s entry in 3D print. Meg Whitman’s comments with Cramer

3D Printing. Thoughts from Greg

HP’s Meg Whitman talked to Jim Cramer on CNBC yesterday and mentioned, again, HP’s eminent plan to enter the 3D market, possibly this calendar year (this blogger is not of the opinion the product will be to market in a substantial way by the end of HP’s fiscal close in October as some suggest––see below).

This topic has been discussed ad nauseam on-line, but here are my points about the interview:

1) It will be very interesting to see what happens in the market and positioning with current 3D giants Stratasys and 3Dsystems. HP is going squarely after their sweet spot, the higher-end market space. Ms. Whitman refers to this as the “enterprise” space.

2) I think any business in the 3D print space, manufactures of printers, software vendors, and service providers will benefit by the trickle down affect as this giant enters the market. Long term, the playing field will define…

View original post 252 more words

3D Printing Showcase at IndusPRINT 2014

Inkjet Forum India always gets innovative with every conference that’s held. After a series of comprehensive events on Digital Textile Printing and establishing the “Inkjet India” flagship conference brand worldwide, Inkjet Forum India has developed a knowledge transfer platform for the currently fast evolving industrial printing segment. The company brings to you a ‘3D Printing Showcase’ which will be co-located with IndusPRINT 2014 – the first conference in Asia, which is specifically focused towards industrial inkjet and printing technology. This conference will examine the emerging applications for inkjet and print such as product decoration, labeling & packaging & functional deposition.

3D Printing technologies are rapidly gaining ground and radically changing the landscape of prototyping, additive manufacturing and product development. According to MarketsandMarkets, the 3D printing market is expected to grow at a CAGR of 23% from 2013 and reach $8.41B in 2020. India with its large pool of engineering & creative talent will be the market to watch out for in the next 5 – 10 years. The 3D Printing Showcase will be a part of IndusPRINT 2014 – The first conference in India, which is specifically focused towards

industrial inkjet, printing technology & 3D Printing. This conference will examine the emerging applications for inkjet and substrate deposition. The showcase will consist of live demo of a 3D design printed into an object, Industrial applications of 3D, Additive Manufacturing vs 3D Printing, Applications of 3D Printing & 3D startups in Asia/India.

Speakers from the areas of Digital, Screen, Functional & 3D printing will share their knowledge on the current technology and market trends. The Speakers will comprise of Mr. James Gill, who will speak on “How Digital Inkjet is changing the Industrial process”. Amongst the others, are Mr. Bharghav Mistry who is a firm believer in screen-printing technology will speak on “Innovations in Industrial Screen Printing”. Mr. Stewart Partridge will provide valuable insight into industrial printing with his experience ranging from screen printing to cutting edge industrial inkjet printing. Mr. Frazer Chesterman with his experience at FESPA, FM Brooks and in understanding the trends of printing across segments will speak on the market trends of Industrial Printing in Europe and Ms. Debbie Thorp, Director, Global Inkjet Systems Ltd (GIS) will bring in her 2 decades of digital printing experience to IndusPRINT 2014.

IndusPRINT 2014 will provide the delegates a platform to network with industry experts, to discover pioneering printing technologies, to stay updated latest technology developments and to adopt them successfully in their manufacturing processes to boost business opportunity. Leading technology providers from the decorative and functional printing sector will showcase innovative technology and manufacturing techniques to enhance the production process and lend it flexibility.

About Inkjet Forum India

Inkjet Forum India strives to lead the industry towards innovation in Inkjet! Our primary objectives comprise of assisting the printing industry to upgrade with technological developments, understand various applications & market trends in the areas of digital textile printing, ceramic inkjet printing, industrial inkjet & printing inks. We also possess the experience in hosting the most comprehensive and informative conferences and seminars for the Indian inkjet industry.

Contact

Divya Vinekar,

Email: divya@inkjetforumindia.com

Additive Manufacturing – A new industrial revolution?

You name it and 3D Printing will manufacture-it-all. From a pin to a piano, 3D printing has been one of the most rapidly emerging and eagerly followed applications of Inkjet and deposition technology. The latest additions include a House, a Kidney, a gun, 3D printed meals and so much more.

3D printing is the broader term for tool-less manufacturing methods which enable to manufacture components from digital data layer upon layer. This tool-less production method changes the approach to manufacturing profoundly and thus allows completely new design freedom. Additive Manufacturing is the process of joining materials to make objects from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing methodologies. The most common additive manufacturing methods utilize this layered approach, but other geometries are also possible.

There are many reasons for the success of this technology and the great interest it has aroused. Potentials for a reduction of costs in stock-keeping and logistics are just a prelude. However, 3D printing also gives many causes for controversial discussions with regard to subjects like copyright and protection of intellectual property. In many cases, 3D printing is already an excellent method to accelerate development processes and to satisfy special wishes. Special applications, too, like light-weight construction and space-saving, compact designs are promising fields of activity for the additive manufacturing methods. Design engineers who combine the traditional engineering know-how with the design options of 3D printing are ahead of the game when it comes to optimising the performance of assembly modules.

There are various sub-technologies which constitute additive manufacturing or 3D Printing

Classification of additive manufacturing:

1) Selective Laser Sintering (SLS) and Selective Laser Melting (SLM)

In SLM & SLS the metal or plastic powder is melted by the energy of a laser beam or E-Beam and the required parts are built up. The powder which is not melted is removed after finishing the laser process.

Materials: Plastics (SLS), Metal (SLM).

Applications: With this technology prototypes and small batches of parts are produced. It is also used to repair and to build up material. Production of tools is a future application under development for this technology.

2) Fused Deposit Modeling (FDM)

In this process, a plastic or wax material is extruded through a nozzle that traces the part’s cross sectional geometry layer by layer. The build material is usually supplied in filament form, but some setups utilize plastic pellets fed from a hopper instead. The nozzle contains resistive heaters that keep the plastic at a temperature just above its melting point so that it flows easily through the nozzle and forms the layer. The plastic hardens immediately after flowing from the nozzle and bonds to the layer below.

Materials: ABS, polyamide, polycarbonate, polyethylene, polypropylene, and investment casting wax.

Applications: Form/fit testing, Functional testing, Rapid tooling patterns, Small detailed parts,Presentation models, Patient and food applications, High heat applications

3) Stereolithografie/Digital Light Processing

SLA uses a UV laser to trace out successive cross-sections of a three-dimensional object in a vat of liquid photosensitive polymer. As the laser traces the layer, the polymer solidifies and the excess areas are left as liquid. The platform is lowered by a distance equal to the layer thickness, and a subsequent layer is formed on top of the previously completed layers. This process of tracing and smoothing is repeated until the build is complete. Once complete, the part is elevated above the vat and drained. Excess polymer is swabbed or rinsed away from the surfaces.

Materials: Thermoplastics (Elastomers)

Application: Form/fit testing, Functional testing, Rapid tooling patterns, Snap fits, Very detailed parts, Presentation models, High heat applications

4) Laminated Object Manufacturing (LOM)

Parts are produced by stacking, bonding, and cutting layers of sheet material on top of the previous one. A laser cuts the outline of the part into each layer. After each cut is completed, the platform lowers by a depth equal to the sheet thickness and another sheet is advanced on top of the previously deposited layers.

Materials: Thermoplastics such as PVC; Paper; Composites (Ferrous metals; Non-ferrous metals; Ceramics)

Applications: Form/fit testing, Less detailed parts, Rapid tooling patterns

5) Photopolymer Inkjet Printing (PIP)

PIP is an additive process that combines the techniques used in Inkjet Printing and Stereolithography. The method of building each layer is similar to Inkjet Printing, in that it uses an array of inkjet print heads to deposit tiny drops of build material and support material to form each layer of a part. However, as in Stereolithography, the build material is a liquid acrylate-based photopolymer that is cured by a UV lamp after each layer is deposited. The advantages of this process are very good accuracy and surface finishes. However, the feature detail and material properties are not quite as good as Stereolithography.

Materials: Thermoplastics such as Acrylic (Elastomers)

Application: Form/fit testing, Very detailed parts, Rapid tooling patterns, Presentation models, Jewelry and fine items

6) 3D Printing

The process is similar to the Selective Laser Sintering (SLS) process, but instead of using a laser to sinter the material, an ink-jet printing head deposits a liquid adhesive that binds the material. Material options, which include metal or ceramic powders, are somewhat limited but are inexpensive relative to other additive processes. 3D Printing offers the advantage of fast build speeds, typically 2-4 layers per minute. However, the accuracy, surface finish, and part strength are not quite as good as some other additive processes. 3D Printing is typically used for the rapid prototyping of conceptual models

Materials: Ferrous metals such as Stainless steel; Non-ferrous metals such as Bronze; Elastomers; Composites; Ceramics

Applications: Concept models, Limited functional testing, Architectural & landscape models, Color industrial design models, Consumer goods & packaging

Additive manufacturing due to the shear scale of materials being used and the applications being targeted has surely brought upon a new industrial revolution and is threatening to change the way we manufacture or do business !

References

A 3D printed house

3D printing has become an integral part of architecture. At first there were presentation models, followed by living spaces, and most recently the question was: Who will build the first house using 3D printing technology – and when? Now the guessing game has come to an end: The house has been printed and is located at voxeljet’s service center in Friedberg near Augsburg.

Friedberg, Germany, 15. May 2014 Just how did voxeljet manage to win this race, when the whole world is working on turning this vision into reality? “We ‘only’ printed the house,” says a modest Dr. Ingo Ederer, “the idea and design came from Austrian architect, visionary and cosmopolitan Peter Ebner.”

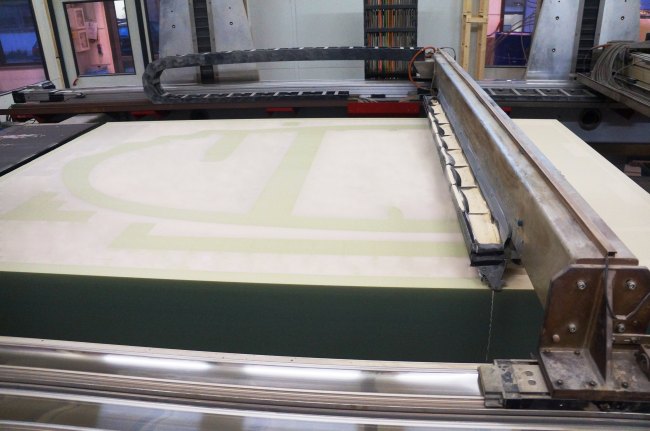

3D printing process on a VX4000

And of course there is a lot of creativity in the design that was created by the architect, who works in Munich and teaches in the US and England, together with his talented students at 3M futureLAB by UCLA + HUD, the University of California, Los Angeles and the Huddersfield University. The house is a completely print-ready unit including toilet, kitchenette, and furniture – all from a 3D printer.

Unpacking of one part

And even though this is not a house with the normal dimensions, but rather a living space reduced to the bare minimum with just a few square meters and a height of approximately three meters, it nevertheless begs the question: What kind of 3D printers can generate sand molds in these dimensions. The term 3D printer is a great understatement when we talk of voxeljet’s large-format machines.

Two printed parts, Picture: Florian Holzherr

“The VX4000, which generated the two sand molds for the house, one piece at a time, using the layer building method, is one of the world’s largest industrial facilities of this kind with a space requirement of 25 x 12 meters and a height of 4.5 meters. The “printer” is actually a small stand-alone factory that produces components at dimensions of up to eight cubic meters using a fully automated process,” says Dr. Ederer. “Architectural projects such as this house would be impossible to create using 3D printing technology without such printing systems.”

Architect Prof. Peter Ebner, Picture: Florian Holzherr

The VX4000 required a total of 60 hours to print the two house halves. Including everything, the printing costs for the spectacular project totaled approximately EUR 60,000. The small house weighs approximately two tonnes. And: It meets all of the requirements imposed by the architect. Univ. Prof. Peter Ebner is very enthusiastic about the technical execution and the stability of the printing.

voxeljet, www.voxeljet.com

3M futureLAB by UCLA + HUD, www.futurelabstudio.org

SCE, www.sce.de

Florian Holzherr, www.architekturfoto.net

Company Profile:

voxeljet is a leading provider of high-speed, large-format 3D printers and on-demand parts services to industrial and commercial customers. The Company’s 3D printers employ a powder binding, additive manufacturing technology to produce parts using various material sets, which consist of particulate materials and proprietary chemical binding agents. The Company provides its 3D printers and on-demand parts services to industrial and commercial customers serving the automotive, aerospace, film and entertainment, art and architecture, engineering and consumer product end markets.

For more information go to YouTube and follow us on LinkedIn and Facebook.

Contacts

voxeljet:

Stefanie Riker

Tel: +49 821 7483 440

stefanie.riker@voxeljet.de

Investor Relations

Anthony Gerstein

anthony.gerstein@icrinc.com

646-277-1251